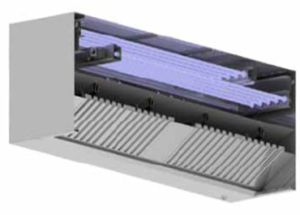

The UV hood combines the effectiveness of traditional filtering systems with the added efficiency of UV lamps that generate ozone in order to break down odors and grease. The air flow that enters, after passing through the labyrinth filters, arrives on the UV lamps and the generated ozone reacts with the grease and the odors to significantly reduce their amounts.

CLEANING AND MAINTENANCE

The maintenance of a UV system requires a cleaning, on average, every

600 hours performed by using a detergent soaked cloth. The UV lamps

have a lifetime of approximately 8000 hours after which they lose their effectiveness.

Any anomaly of the UV lamps is indicated by the turning off of the control LEDs placed on the hood.

UV HOOD INSTALLATION

The UV hood is to be installed similarly to a traditional hood,

where is must be connected to an external extractor of which it will be governed

by an inverter mounted on a control panel characterized by

four speeds.

The purchase of an inverter, specifically designed to work with UV systems, saves energy when operating with

reduced air flow, thereby halving the power of the UV lamps. The inverter has the capability to program the four speeds according

to the characteristics of the system: the first two correspond to the lowest speeds that will only operate half of the lamps,

while the last two correspond to the maximum flow rates of extraction that will put into operation all the lamps simultaneously.

WHAT IS OZONE?

In nature, ozone is a gaseous compound found in the layers of the Earth’s atmosphere

(stratosphere). It is of natural origin and helps to protect life

on Earth by creating a defensive barrier that absorbs the ultraviolet rays of the Sun

letting pass only the UV-A rays. Ozone can be produced

artificially by using UV lamps; it oxidizes the organic matter

breaking down grease and odors in the treated air and then transforming them

respectively into dust and odorless molecules. The ozone generated by the UV lamps

ensures the distribution of bacteria and viruses that normally

generate inside to the extraction plenum.

UV hood

The UV hood combines the effectiveness of the traditional filtering systems with the efficiency of the UV lamps by generating Ozone in order to break down odors and grease. The air flow that enters, after passing through the labyrinth filters, arrives on the UV lamps and the generated Ozone reacts with grease and odors to significantly reduce their amounts.